ZANYO is a leading manufacturer and supplier of high performance vacuum oil purifiers. Our system effectively removes water, gas, and impurities, ensuring high oil purity and extended equipment lifespan. Custom configuration is available to meet your specific needs, ensuring improved oil quality and operational efficiency.

Optional Configurations

- The system can be supplied in a fully enclosed housing that is weatherproof, dustproof, and waterproof, ensuring safe and stable operation outdoors.

- Vacuum pumps, oil pumps, and electrical components are available from various brands, providing flexibility to meet different application requirements and budgets.

- Advanced PLC control allows fully automatic operation.

- Explosion-proof option is available for special working environments.

- Please contact us for customized flow rates or special models. Machine size and weight may vary slightly depending on the selected configuration.

Vacuum Oil Purifier & Oil Maintenance Guide

Main Functions of Vacuum Oil Purification System

- Remove Colors: Eliminates color impurities from oil, improving its appearance and overall quality.

- Remove Moisture: Extracts free, dissolved, and emulsified water to prevent corrosion, oxidation, and degradation of the oil.

- Remove Gas: Removes dissolved gases and air bubbles, reducing oxidation and enhancing the oil’s insulation performance.

- Remove Particles: Filters out solid contaminants such as metal shavings, dust, and carbon residue to maintain oil cleanliness.

- Restore Oil Cleanliness: Enhances oil purity and stability, extending the service life of both the oil and the equipment.

Key Components In a Vacuum Oil Purifier

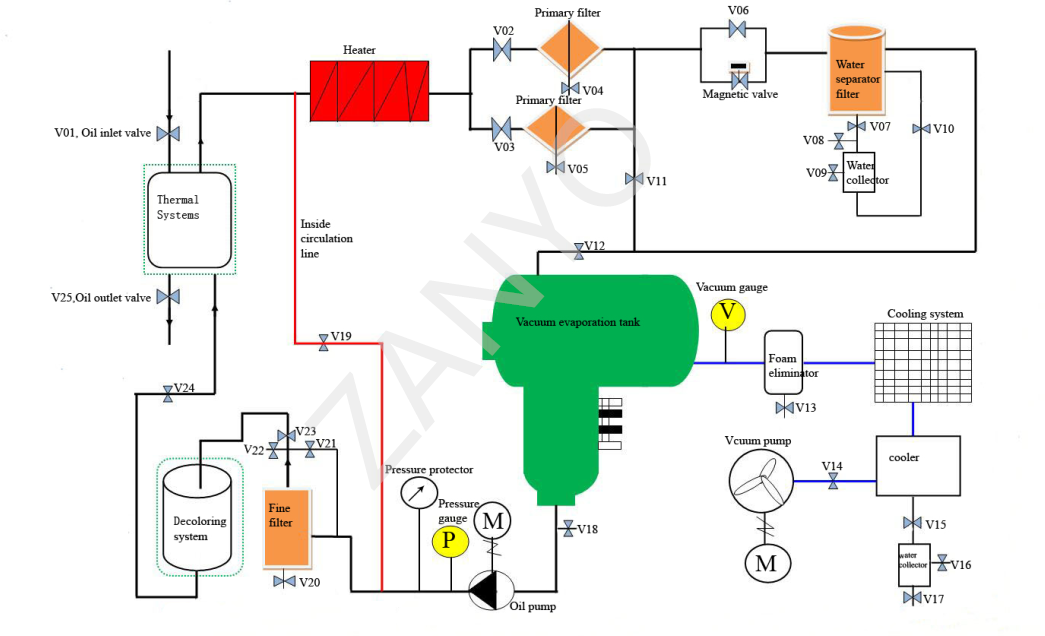

A vacuum oil purification machine includes a heater, primary filter, vacuum chamber, vacuum pump, condenser, oil pump, roots pump, fine filter, piping, valves, and an electrical control system.

The vacuum chamber is where the oil is purified. Oil flows in and out through inlet and outlet ports, while the heater warms it to the optimal temperature for treatment. Filters remove solid contaminants, and the vacuum pump creates the vacuum necessary for moisture, gas, and particle removal. The oil pump ensures continuous circulation of the purified oil.

Vacuum Oil Purifier Working Principle

The operation of a vacuum oil purifier generally follows five steps: heating the oil, primary filtering, removing moisture and gas from the oil, fine filtering, and decoloring.

Step 1: Heating the Oil

The oil is first heated to a specific temperature, usually between 45°C and 60°C. Heating helps release dissolved moisture and other impurities, making them easier to remove in the subsequent steps.

Step 2: Primary Filtering

Heated oil passes through a primary filter to remove larger solid particles such as dust, dirt, and debris. This step prepares the oil for more precise purification in the following processes.

Step 3: Removing moisture and gas from the oil

A high vacuum is created in the purification chamber to remove moisture and gases. Dehydration combines low pressure and high temperature to extract water, while degassing eliminates dissolved gases and air bubbles, improving the oil’s insulation properties.

Step 4: Fine Filtering

After dehydration and degassing, the oil passes through a fine filter to remove any remaining small particles, ensuring high purity and cleanliness.

Step 5: Circulating the Purified

Finally, the cleaned oil is pumped back into the industrial system. Continuous circulation maintains proper insulation, cooling, and overall system efficiency.

Zanyo’s vacuum oil purifier is designed to remove water, gas, and contaminants from industrial oils. It operates by creating a low-pressure environment inside a vacuum chamber. Under reduced pressure, water and dissolved gases evaporate. This process is highly effective for removing free, emulsified, and dissolved water, which standard filtration cannot eliminate.

During operation, oil enters the vacuum chamber, where a heating element raises its temperature slightly to accelerate moisture evaporation. The vacuum pump lowers the pressure, allowing water and gases to vaporize at a much lower boiling point. A separation system collects and removes the evaporated moisture and gases, ensuring only dry and clean oil remains.

Applications of Vacuum Oil Purfication Machine

Transformer Oil Purification

Transformer oil cools and insulates electrical transformers. Over time, it can absorb moisture and gases, reducing its insulating ability. A vacuum oil purifier restores the oil by removing water, gases, and solid impurities, enhancing dielectric strength and extending the operational life of transformers.

Lubricating Oil Purification

Lubricating oils in engines and machinery collect contaminants such as water, dust, and wear particles over time. Vacuum oil purifiers remove these impurities, maintaining oil quality and machinery efficiency, lowering maintenance costs, prolonging equipment life, and improving overall performance.

Hydraulic Oil Purification

Hydraulic oils are susceptible to contamination from water and air, which can affect system efficiency. Vacuum purification removes these impurities, ensuring smooth operation, maintaining proper industrial system function, and extending service life.

Edible Oil Refining

After extraction, edible oils may contain moisture and unwanted impurities. Vacuum oil purifiers remove these substances, improving stability and oil quality.

Industrial Waste Oil Treatment

Used oils can be purified using vacuum oil purifiers to remove contaminants, making them suitable for reuse or safe disposal. This reduces waste, lowers disposal costs, and enables oil recycling.

Why Choose Zanyo As Your Supplier

Equipped with pressure protection, the system operates safely under varying conditions, preventing damage from excessive pressure. PLC control ensures consistent purification with minimal manual oversight, making operation simple and precise.

With global support, fast delivery, and comprehensive after-sales services—including technician guidance and training—ZANYO guarantees a smooth and reliable oil purification experience for clients worldwide.