Reliable Used Engine Oil Recycling Machine China Manufacturer

One of the most effective ways to extend the service life of waste oil is through recycling and purification. By treating deteriorated engine oil, removing contaminants, and restoring its properties, the oil can be reused instead of being drained and discarded. Without on-site regeneration, lubricating oil will inevitably reach the end of its usable life and require replacement.

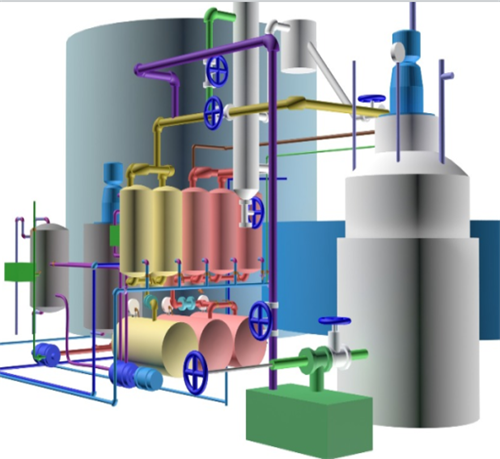

Descriptions of Waste Engine Oil Recycling Machine

The main purpose of the waste engine oil recycling machine would be to regenerate black lube oil, waste engine oil, and some other industrial oils. Water, deeply oxides, gas, asphalt, particles, colloid, free carbon, asphalt, as well as wax can all be effectively separated from oil using an Oil Recycling System, turning black waste oil into a translucent golden tint.

Degassing, dewatering, and decoloring are all functions about an oil recycling plant. To enhance the qualities of engine oil, restore its efficiency, and reduce wear so that the engine can operate normally as well as safely, thus extending the engine’s or oil’s lifespan.

Key Features

How Oil Recycling System Works

Waste oil is injected into the reaction system via an oil pump, where it is mixed with flocculant and decoloring chemicals before being heated. Then, as a result of coacervation in waste oil due to physical, chemical, as well as sorption factors, the electric-charged particle becomes a large one.

Simultaneously, hazardous gases are eliminated by degassing as well as dewatering, followed by chilling and filtering. The oil is next filtered via a high-precision sieve to remove contaminants, yielding pure oil with regeneration like base oil. Hydraulic oil recycling is another method of oil filtration in an oil recycling plant.

On-site oil recycling is possible in some cases. If your company generates a considerable amount of old oil which can’t be retrieved, it could be converted into lubricating oils or fuel for boiler, commercial furnaces, and other applications.

If the used oils should be sent offsite since they are very contaminated with varying viscosity/base oils as well as chemicals, or the plant just doesn’t have enough volume to validate on-site recycling, make sure that the used oils are managed and delivered in an environmentally appropriate fashion by a waste removal/recycling corporation.

Utilized oil could be processed to lubricants, converted into fuel oils, and is utilized as a raw material within the refining along with petrochemical sectors. Used oil filters also include reusable scrap metal that steel makers could use as scrap feed.

So, how then do you recycle spent oil?

Spent oil is recycled through a process called re-refining. This method removes contaminants and restores the oil to a condition comparable to new, virgin oil. Re-refined oil must meet the same strict refining, blending, and performance standards required for new lubricating oil.

Laboratory tests and real-world applications have confirmed that re-refined oil matches, and sometimes exceeds, the performance of virgin oil.

Re-refined oil can be used in the same applications as new oil, including automotive engines, heavy-duty diesel engines, and other internal combustion engines. It is suitable for car service centers, industrial machinery maintenance, and fleet operations.

For large users, such as fleet maintenance companies, it is possible to establish a closed-loop system. They can collect their used oil, send it for re-refining, and receive back high-quality re-refined oil for continuous use.

Applications of Used Oil Recycling Machine

Recycled motor oil could be used as a fuel in space heaters, boilers, and industrial heating purposes including blast furnaces including cement kilns. In a procedure like oil re-refining, except the final hydro treatment, recycled motor oil could be distilled to diesel fuel as well as marine fuel.

Benefits of Recycling and Reusing Waste Engine Oil

Recycling and recycling spent motor oil is a better option than throwing it away, and it can save the environment. Recycled old motor oil could be processed into new oil, converted into fuel oils, and are used as petroleum industry raw resources.

Used oils from vehicles, bikes, and lawnmowers, like engine lubricating oil, hydraulic fluids, as well as gear oils, can contaminate the environment when they’re not recycled or disposed of appropriately. To avoid damaging the environment, used oil should be appropriately disposed by municipal waste management authorities or automobile repair businesses.

Why Choose ZANYO?

ZANYO is leading China Company manufacturers create products and services that are focused upon productivity, environmental conservation, and safety, as well as energy consumption. All our products have passed CE and ISO testing and have received certificates.

We use a unique evaporation technology based on the use of suitable materials. All the goods can achieve automation control as well as testing, as well as an automatic defoaming system, facilitating human operation and maintenance.

Get In Touch With ZANYO Waste Engine Oil Recycling Machine

The term “used oil” refers to any petroleum-based and synthetic oil that has been utilized. Our automobiles, lawnmowers, and a variety of other devices all run on oil. Nevertheless, contaminants such as metal scrapings, water, dirt, or chemicals can combine with the oil during routine use, causing the oil to lose its effectiveness over time.

To handle used oil properly and maximize its value, investing in ZANYO’s waste engine oil recycling machine is a smart solution.

FAQs

Is it possible to recycle used engine oil?

Yes, used engine oil can be recycled. Recycling involves removing dirt, water, and other impurities from the old oil so it can be used again. Instead of throwing it away, recycled oil can help save resources and protect the environment. Many industries use waste engine oil recycling machine to make the process fast and efficient.

What is the best way to recycle engine oil?

The best way to recycle engine oil is by using an engine oil recycling machine. These machines clean and restore the oil’s properties, allowing it to be reused safely. Recycling oil helps companies reduce costs, lower waste, and avoid the risks of transporting hazardous oil. It is a simple and eco-friendly solution for extending the life of lubricants.

How should you dispose of your old engine oil?

Old engine oil should never be poured into the ground, drains, or trash. It must be collected in a clean, sealed container and taken to a recycling center or handled by a licensed waste oil service. Proper disposal helps prevent pollution and ensures the oil can be recycled or treated safely.

What can you use old motor oil for?

Old motor oil, once properly recycled, can be reused as lubricant for machinery or even processed into new products like industrial fuel oils. With the right treatment, old oil is not waste — it becomes a valuable resource again. Recycling helps reduce the need for new oil and supports a cleaner environment.