Vacuum Transformer Oil Purifier Performance

ZYD-II series Double Stages Vacuum Transformer Oil Purifier (also known as Transformer Oil Filtration Machine or Vacuum Transformer Oil Purifier) can effectively remove moisture, gas, solid impurity from old or new transformer oil, to improve the flash point and dielectric strength value of insulation oil. ZYD-II can increase the dielectric insulation value more than 35KV at one time. It suits for purifying all kinds of insulation oil, especially suits for purifying transformer oil from 110KV and above 110KV UHV power transmission and distribution projects; also suits purifying of capacitor oil, mutual inductor oil, switch oil, cable oil.

ZYD-II adopts “T” type vacuum evaporation tank, it separates the evaporation tank and the oil tank, improving evaporation efficiency, prolong the machine lifetime.

- Removing Moisture. The final treated oil can achieve less than 3ppm

- Degassing. The final treated oil can achieve less than ≤0.05%

- Removing Particles. The final treated oil can achieve1 micrometer

- Vacuum oil injecting

- Vacuum drying equipment for transformers

- Vacuum purification online work, unattended operation.

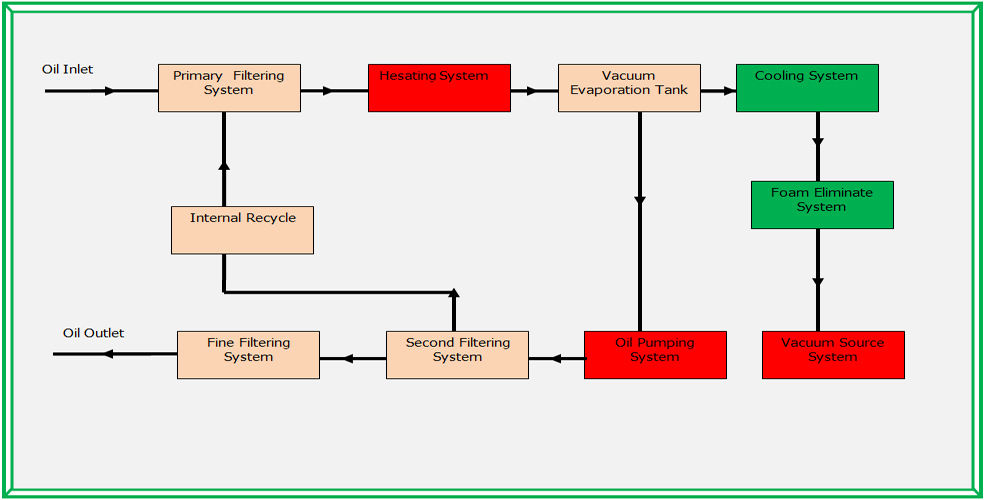

Working Principle

Water dissolves in transformer oil until the oil internal pressure is balanced . If the pressure, temperature, and saturation which associated with the balance pressure are broken, transformer oil either overflows or absorbs moisture until get to a new balance under new conditions. For ZYD-II series Vacuum Transformer Oil Purifier, the working vacuum is less than 133pa, it can atomize oil into less than 50um, so it can quickly reduces moisture content to less than 3ppm.

Technical Features

- “T ”type double vacuum separation technology, double stages thin film drying degassing technology, double evaporation area and degassing time.

- Patented degassing tank: anti-foam structure & Dual electronic foam monitoring system “( key components are from Switzerland), completely eradicating oil entering into vacuum pump.

- Oil atomized particles size is less than 50um, largely increasing efficiency for water molecules and gas molecules escaping from oil molecules.

- Vigorously increase contact area between heater and oil (2w/cm2), reduce the surface temperature of heater, and prevent oil cracking and aging.

- Vacuum pump cooler preposition, to reduce water get into vacuum pump, reduce the frequency to change vacuum pump oil and extend vacuum pump lifetime.

- High precision filtering element, fine accuracy is 1 micron(optional: 0.5 micron),β≥1000.

- Adopt the high pressure oil pump, oil transmission stable, low noise, long life

- Using famous brand high quality components, performance is stable and reliable.

- Automatic float ball & electronic oil level automatic controlling system, to realize automatic bubble elimination, unattended operation.

- Easy operation and trouble reminder and trouble shooting tips.

Safety Configuration

- Control System: Optimized design of control interlock protection device, overpressure alarm and protection, phase sequence protection, to ensure whole machine working stably for a long time. Automatic pressure alarm system, automatic overload protection system, automatic constant temperature system, automatic bubble elimination system, automatic protection of blowout prevention and other advanced technologies, to ensure the safe operation of untended operation.

- Adopt interlocked protective system, which connect oil pump, heater and liquid level sensor, avoiding blank heating, blank pumping, oil leak and electricity leak.

- Outlet oil pressure protector, to monitor pressure of oil filters all the time, effectively protecting machine and operators.

- To install liquid level and temperature protector of heater, prevent instantaneous high temperature of heater.

Technical Parameters

| Index name | unit | 30 | 50 | 100 | 150 | 200 | 250 | 300 |

| Flow rate | L/Min | 30 | 50 | 100 | 150 | 200 | 250 | 300 |

| Working vacuum | Pa | ≤133 | ||||||

| Working pressure | MPa | ≤0.5 | ||||||

| Gas content | % | ≤0.05 | ||||||

| Temperature range | °C | 20°C~ 60°C(68°F ~ 140°F) | ||||||

| Power supply | As per user’s option | |||||||

| Working noise | dB(A) | ≤65 ~ 85 | ||||||

| Heating power | Kw | 24 | 30 | 60 | 90 | 125 | 136 | 151 |

| Total power | Kw | 27 | 35.5 | 68 | 105 | 135 | 148 | 168 |

| Inlet(Outlet) | mm | φ32 | Φ25 | Φ44 | Φ50 | Φ58 | Φ60 | Φ65 |

| Weight | kg | 520 | 570 | 920 | 1000 | 1300 | 1800 | 2200 |

| Dimension | L | mm | 1550 | 1550 | 2000 | 2150 | 2250 | 2300 |

| W | mm | 1200 | 1200 | 1250 | 1300 | 1300 | 1350 | |

| H | mm | 1750 | 1800 | 2150 | 2250 | 2250 | 2300 | |

Optional Configuration

Vacuum Pump: Atlas, Leybold ,Busch,Joysun,Hokaido Etc.

Oil Pump: Italy Seim Screw Oil Pump, Germany KRACHT, Tianjin Screw Oil Pump, Etc.

Electrical: Siemens, Schneider.

Other : PLC Controlling System, Enclosed Doors.

Oil Testers: BDV Oil Tester, Moisture Sensor, Flow Meter Etc.

Technical Performance

After oil filtration treatment, the following indexes are achieved:

| Breakdown Voltage Value | ≥70KV |

| Fine Filter Precision | ≤1μm |

| Gas Content | ≤0.05% |

| Water Content | ≤3ppm |

| Working Temperature | 40-70℃ |

| Working Vacuum | ≤80pa |

| Ultimate Vacuum | ≤5pa |

Applications of ZYD-II High Vacuum Transformer Oil Purifier

The ZYD-II High Vacuum Transformer Oil Purifier is widely used in the power industry, manufacturing plants, and maintenance facilities. Its advanced dehydration, degassing, and filtration technologies make it suitable for the following applications:

-

Power Transformers – Efficient purification of insulating oil to maintain dielectric strength and extend transformer lifespan.

-

On-Site Transformer Maintenance – Ideal for high-voltage substations and power plants requiring quick and reliable oil treatment.

-

Industrial Equipment – Purification of insulating oils used in reactors, capacitors, circuit breakers, and high-voltage switches.

-

Electric Utility Companies – Regular oil regeneration to ensure stable operation of transmission and distribution systems.

-

Heavy Machinery and Manufacturing – Maintenance of insulating oils in large-scale industrial machinery and electrical equipment.

-

Oil Filling & Filtering – Used during transformer installation or repair to ensure clean and moisture-free insulating oil.

Packaging Solutions

Protective Wrapping

Before shipment, the whole machine is carefully covered with protective film to guard against dust, moisture, and minor scratches.

Export-Standard Wooden Case

The entire unit is securely placed into one customized wooden case. The strong wooden structure prevents damage from impact and vibration during long-distance transport.

Moisture-Proof Treatment

Anti-rust and moisture-proof measures are applied inside the case to protect the purifier’s core components during sea or land shipment.

Customized Options

Different case sizes and reinforcement methods can be provided based on shipping requirements. OEM labeling is also available for international clients.

Why Choose Zanyo

- Extended Warranty: Each ZYD-II unit comes with an 18-month warranty, ensuring long-term reliability.

- Proven Industrial Reliability: Advanced vacuum and filtration technologies maintain continuous operation even in demanding environments.

- Professional Support: Zanyo provides technical guidance, spare parts supply, and after-sales support tailored for business clients.

- OEM & Wholesale Expertise: Whether you need a single customized unit or multiple machines for large-scale deployment, Zanyo can fulfill your specifications efficiently.

- Global Reputation: Trusted by industrial clients and energy providers worldwide for delivering durable, high-performance transformer oil purification systems.

FAQ

What is the main function of the ZYD-II High Vacuum Transformer Oil Purifier?

It removes moisture, gas, and impurities from transformer oil, improving its dielectric strength and extending transformer service life.

What types of oil can this purifier handle?

It is mainly designed for transformer oil but can also be used for insulating oils in high-voltage switchgear, capacitors, and other electrical equipment.

How often should the filters be replaced?

Filter replacement depends on the oil condition and operating frequency. In general, filters should be checked every 3–6 months.