ZYD-II 4200L/Hr High Vacuum Dielectric Oil Purification System adopts touch screen, It has fine performance. reasonable structure, during operation processing, it allows adjustment of two types of manual and automatic mode of operation

ZYD-II is Double Stages High Vacuum Dielectric Oil Purification System, efficiently remove moisture, gas and impurities from insulation oil, and improve oil dielectric insulation value and oil quality, to ensure the safety of power equipment.

ZYD-II is especially suitable for deep treating of the high grade transformer oil, ultra high transformer oil, it especially suits for purifying transformer oil from 110KV and above 110KV UHV power transmission and distribution projects;

Performance of Vacuum Dielectric Oil Purification System

- Removing Moisture. The final treated oil can achieve less than 3ppm

- Degassing. The final treated oil can achieve less than ≤0.05%

- Removing Particles. The final treated oil can achieve1 micrometer

- Vacuum oil injecting

- Vacuum drying equipment for transformers

- Vacuum purification online work, unattended operation.

What Is a Dielectric Oil Purification System?

A dielectric oil purification system removes contaminants from insulating oil, restoring dielectric strength, reducing moisture and dissolved gases, and filtering particles. It is widely used for transformer and turbine oils to maintain performance and extend equipment life. By improving degraded oil, the system reduces the risk of partial discharge, insulation aging, and equipment failure.

4200 L/Hr Dielectric Oil Purification System Advantages

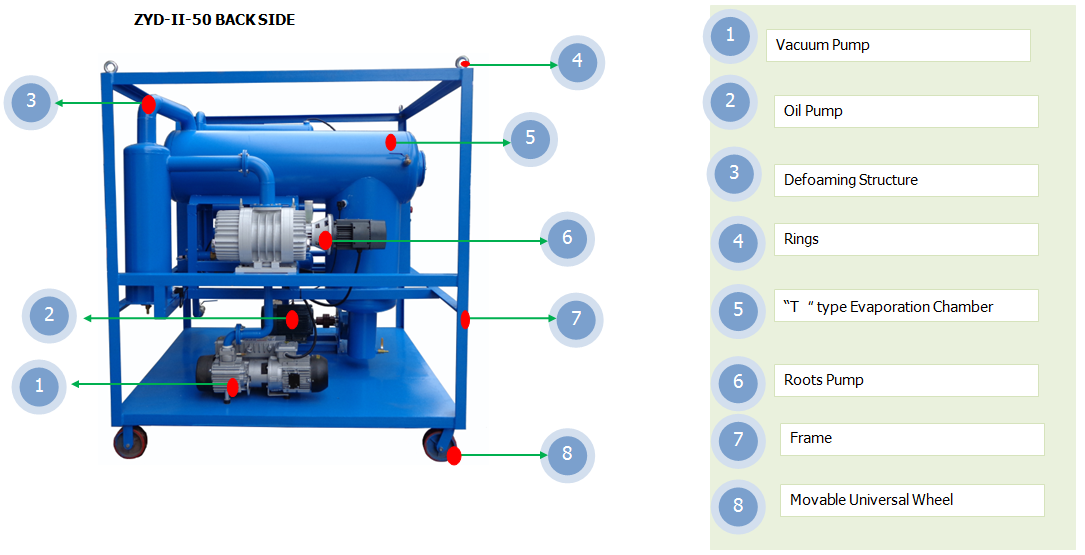

Equipment Appearance of the Dielectric Oil Purification System

Applications of Dielectric Oil Purification

Power Transformers and Substations

Dielectric Oil Purification Systems are widely used for oil treatment in power transformers, substations, and distribution networks. They help maintain insulation performance in high-voltage and extra-high-voltage equipment.

Electrical Equipment Manufacturing and Maintenance

Transformer manufacturers and service providers use dielectric oil purification during production testing, commissioning, and scheduled maintenance to ensure oil quality meets technical standards.

Renewable Energy and Industrial Power Systems

Wind farms, solar substations, and industrial power plants rely on purified insulating oil to maintain safe operation under variable load conditions and harsh environments.

High Vacuum Dielectric Oil Purification System | ZANYO

The ZANYO Dielectric Oil Purification System is designed to treat a wide range of insulating oils used in high-voltage and industrial electrical equipment. Its advanced purification technology ensures stable performance across multiple oil types, including:

- Transformer Oil: Ideal for power and distribution transformers, maintaining high dielectric strength and extending equipment lifespan.

- Capacitor Oil: Ensures clean, gas-free oil for high-voltage capacitor insulation.

- Reactor Oil: Suitable for oil-filled reactors and inductors, improving insulation reliability under load.

- Switching Oil: Used in circuit breakers and switchgear to prevent moisture-related failures.

- Refrigerating Oil: Supports industrial refrigeration systems requiring clean, dry dielectric fluid.

- Other Insulating Oils: Can be applied to specialized industrial oils with similar dielectric properties.

Technical Parameters of the Purification System

| Index name | unit | 70 |

| Flow rate | L/Hr | 4200 |

| Working vacuum | Pa | ≤133 |

| Working pressure | MPa | ≤0.5 |

| Temperature range | °C | 20°C ~ 60°C(68°F ~ 140°F) |

| Power supply | As per user’s option | |

| Working noise | dB(A) | ≤65 |

| Heating power | Kw | 60 |

| Total power | Kw | 68 |

| Inlet(Outlet) | mm | Φ44 |

| Weight | kg | 920 |

| Dimension (L) | mm | 2000 |

| Dimension (W) | mm | 1250 |

| Dimension (H) | mm | 2150 |

Optional Configuration of the Dielectric Oil Purification

Vacuum Pump: Atlas, Leybold ,Busch,Joysun,Hokaido Etc.

Oil Pump: Italy Seim Screw Oil Pump, Germany KRACHT, Tianjin Screw Oil Pump, Etc.

Electrical: Siemens, Schneider

Other : PLC Controlling System, Enclosed Doors,

Oil Testers: BDV Oil Tester, Moisture Sensor, Flow Meter Etc.