Ultra High Voltage Transformer Oil Purifier Descriptions

This Transformer Oil Purifier is Especially for ultra-high voltage project as ( 1000KV, ±800KV, 750KV, ±660KV) Substation Maintenance Contractors and Utilities need an transformer oil treatment that can quickly and reliably process transformer oil to meet or exceed very stringent specifications;

In order to achieve optimal dielectric strength and insulating performance inside of transformers and circuit breakers, dielectric oils must be kept absolutely clean and dry;

ZANYO designs and manufacture the most effective, durable, and user-friendly machine running and serving customers in 40 more countries with good reputation.

Functions

- Degassing: to remove other dissolved combustible gases such as Acetylene, Ethylene, Ethane, Methane, Hydrogen and Carbon Monoxide, and Carbon Dioxide.

- Dehydrating: to remove free and dissolved water, including insulation dry-out of the windings.

- Solid particles Removing: to remove solids particles.

- Decoloring and recycling: to remove acids and make the oil color good.

Technical Features

- Specially designed the evaporation chamber(clients can choose), to make larger space for degassing and dehydration.

- To adopt with auto- pressurization defoaming technology, more than 200 hours of continuous operation without bubbles rise.

- Unique technology: Atomizer is placed inside at the bottom of the chamber, to increase the evaporation area and extend the degassing time.

- To adopt vacuum balance pressure technology, vacuum pumping efficiency increased by 50%.

- Advanced level control system, continuously oil supply to prevent oil pyrolysis.

- Advanced level control system.

- PLC controlling system.

- All parts are from world’s famous brands.

How UHV Vacuum Transformer Oil Purifier Works

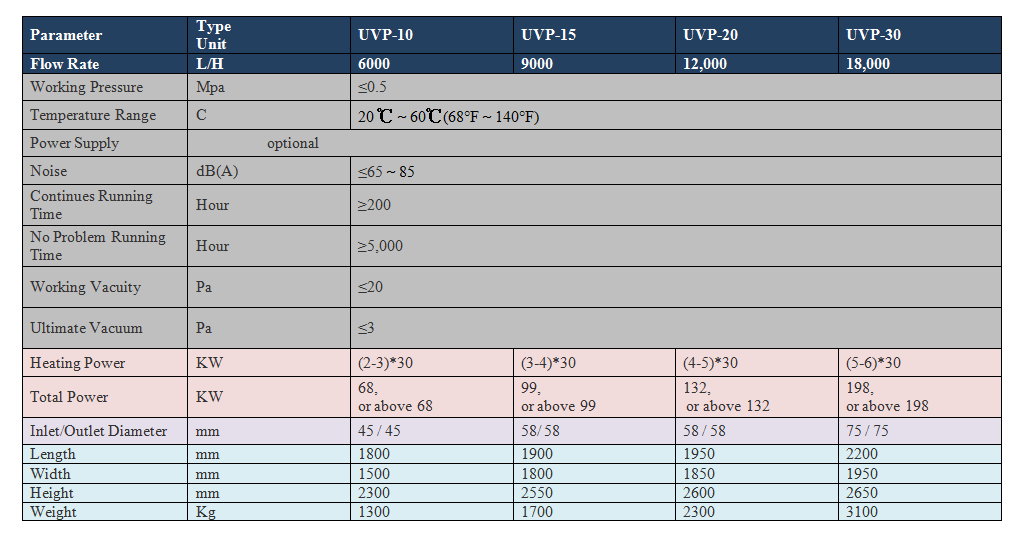

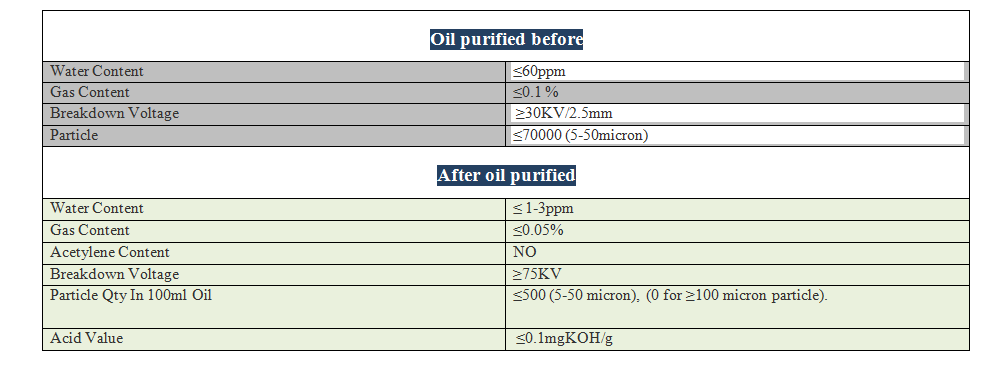

Specifications of Ultral High Voltage Series

Understanding Transformer Oil and Its Role in UHV Power Systems

In ultra-high voltage (UHV) power systems, transformers are responsible for transmitting massive amounts of electrical energy across long distances. To operate safely and efficiently, these transformers rely on insulating oil that both insulates internal components and dissipates heat generated during operation.

However, over time, the oil becomes contaminated with moisture, dissolved gases, and fine particles due to temperature fluctuations, oxidation, and contact with air. Even a small increase in moisture content can drastically reduce the oil’s dielectric strength, leading to insulation failure and transformer breakdown.

To prevent this, power companies use transformer oil purifiers, specialized systems designed to restore oil purity and maintain insulation stability across high-voltage equipment.

Why Oil Purification Is Critical for UHV Systems

UHV transmission systems, typically operating at 500kV–1100kV AC or ±800kV DC, demand extreme insulation performance. Any impurity in transformer oil can cause localized electric field distortion, resulting in partial discharge, thermal stress, and eventual insulation breakdown.

By continuously maintaining oil purity, transformer oil purifiers:

- Prevent insulation failure caused by moisture and gas.

- Reduce aging of transformer insulation materials.

- Extend the service life of transformers and switchgear.

- Improve operational reliability across entire UHV transmission networks.

For national grids and large-scale power projects, the cost of preventive oil purification is negligible compared to the risk of transformer failure.

Benefits for UHV Transmission and Substation Operations

- Enhanced Insulation Reliability: Purified oil prevents breakdown under extreme voltages, improving overall transformer stability.

- Extended Transformer Lifespan: Regular purification reduces chemical degradation and sludge formation.

- Improved System Efficiency: Clean oil allows better heat dissipation and lower internal losses.

- Reduced Maintenance Costs: Preventive purification lowers the frequency of oil replacement and component failures.

- Environmental Protection: Reusing purified oil minimizes waste and supports sustainable energy operations.

Applications Across the Power Industry

- UHV AC and DC transmission systems

- Large transformer substations

- Power generation and grid maintenance facilities

- Industrial electrical equipment maintenance