Performance and Usages

The ZYD-II model Transformer Oil Purifier, with a capacity of 12,000 L/h, is designed for purification and vacuum drying during installation and maintenance of large-scale transformers. It efficiently removes moisture, gas, and solid impurities from both new and used transformer oil, significantly improving its flash point and dielectric strength.

Equipped with a dual-stage vacuum system—one main pump and one booster pump—and a three-dimensional flash evaporation chamber, the unit ensures rapid dehydration and degassing under high-vacuum conditions. It can raise the oil’s dielectric breakdown voltage to over 35 kV in a single cycle, making it ideal for insulation oil used in 110 kV–500 kV and above high-voltage transformers.

In addition to moisture and gas removal, the 12000L/H transformer oil filtration system also performs acid and free carbon removal. It can serve as an independent vacuum source for transformer vacuum drying and oil filling operations.

Functions of 12000L/H Transformer Oil Filtration System

- Removing Moisture. The final treated oil can achieve less than 3ppm

- Degassing. The final treated oil can achieve less than ≤0.05%

- Removing Particles. The final treated oil can achieve1 micrometer

- Vacuum oil injecting

- Vacuum drying equipment for transformers

- Vacuum purification online work, unattended operation.

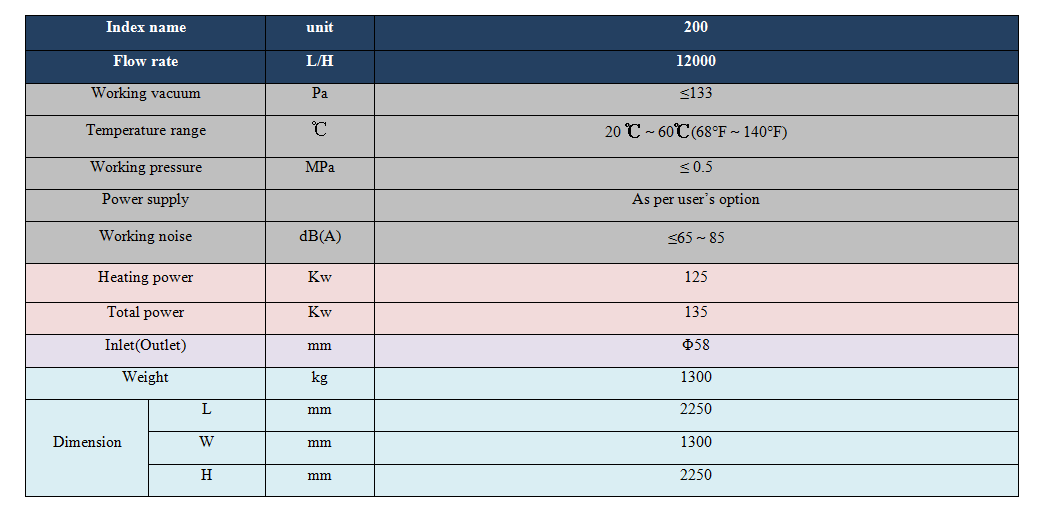

Specifications of 12000L/H Transformer Oil Purification Mahcine

How 12000L/H Transformer Oil Purifer Works

This transformer oil filtration system features a double vacuum tanks that enhances dehydration and degassing efficiency. It combines vacuum separation, precision filtration, molecular adsorption, and vacuum drying to achieve deep purification.

The system effectively removes moisture, gases, solid particles, free carbon, acids, and colloids. After treatment, the insulation oil restores its dielectric strength and clarity, allowing it to perform like new oil and ensuring reliable transformer performance.

Technical Features

The 12000L/H double-stage vacuum oil filtration and purification system features a compact structural design, making it easy to move. Incorporating advanced technologies and innovative designs from both domestic and international oil purification industries, it stands at the forefront of oil treatment technology and performance, offering high vacuum levels, excellent purification efficiency, and precise filtration accuracy.

- Control System: Optimized design of control interlock protection device, overpressure alarm and protection, phase sequence protection, to ensure whole machine working stably for a long time. Automatic pressure alarm system, automatic overload protection system, automatic constant temperature system, automatic bubble elimination system, automatic protection of blowout prevention and other advanced technologies, to ensure the safe operation of untended operation.

- Degassing And Dehydration System: Adopting advanced atomizing system, three-dimensional separation tower and flash evaporation technology, it can quickly remove moisture and gas from the oil by forming parabolic in the special designed vacuum tank.

- Oil Filtration System: Adopt high quality filter element, multi-stage precise filtration, and level-by-level encryption technology, which can remove fine impurities and absorb large amount of pollution. Primary filter can be cleaned and used repeatedly without secondary pollution. High precision filtering element, fine accuracy is 1 micron(optional: 0.5 micron),β≥1000.

- Heating System: by using of high quality heating elements, excellent corrosion resistance, thermal stability, viscosity resistance, insulation, chemical resistance and wear resistance. The safe and reliable carbon fiber heating system with the functions of quickly heating, heating uniform, etc..

- Oil Transferring System: adopt to choose different type of oil pump according to the oil quality and oil viscosity. Special material and special performance curve ensure that oil flowing will never cause gap discharge to bring acetylene, oil treatment process and equipment performance is in the leading position.

- Transformer Oil Recycling System(optional): It can quickly remove carbon deposition from transformer oil which caused by arc, to make the inferior oil quality reach new oil standard.

Technical Performance Indicators

After oil filtration treatment, the following indexes are achieved:

| Breakdown Voltage Value | ≥70KV |

| Fine Filter Precision | ≤1-3μm |

| Gas Content | ≤0.05% |

| Water Content | ≤3ppm |

| Working Temperature | 40-70℃ |

| Working Vacuum | ≤133pa |

| Ultimate Vacuum | ≤5pa |

When a 12000L/H Transformer Oil Purifier is Needed

A 12000L/H transformer oil purifier is ideal for large transformer maintenance and high-voltage applications in power substations and industrial plants.The double-stage vacuum system efficiently removes water, gas, and impurities with deeper dehydration and degassing performance. This high-capacity model suits 110kV and above transformers or operations in humid and contaminated conditions.

This system delivers faster purification and continuous performance, minimizing downtime during installation or overhaul. The 12000L/H double-stage purifier offers reliable moisture control and clean oil circulation, making it the preferred solution for facilities requiring fast, large-volume oil treatment with consistent quality and long-term equipment protection.

Custom Configuration Options

- Vacuum Pump: Available brands include Atlas, Leybold, Busch, Joysun, and Hokaido, ensuring reliable and efficient vacuum performance.

- Oil Pump: Equipped with premium pumps such as Italy SEIM screw oil pump, Germany KRACHT, or Tianjin screw oil pump, selected based on oil viscosity and system requirements.

- Electrical Components: Siemens and Schneider electrical parts provide stable and safe operation.

- Control and Monitoring: PLC control system with touch screen interface for intelligent operation; optional BDV oil tester, moisture sensor, and flow meter for real-time oil quality monitoring.

- Additional Options: Custom options include enclosed doors, mobile trailer, integrated lighting, tool box, and specially designed frame structures for enhanced mobility and protection.