High Performance Vacuum Pump Systems China Manufacturer & Supplier

Zanyo Vacuum Pumps and Systems

Descriptions of Vacuum Pump Systems

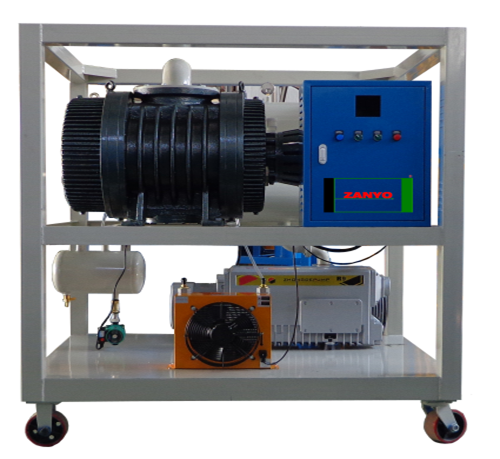

Zanyo’s vacuum pumps and systems are engineered for high-performance applications requiring deep, stable vacuum levels. Combining a Roots pump with a rotary vane vacuum pump, this system delivers superior efficiency and reliability, making it ideal for industries such as semiconductor manufacturing, packaging, material science, chemical processing, and scientific research. Whether you’re handling sensitive materials or performing precise operations, our vacuum pump system is designed to meet the most demanding requirements.

- High-Efficiency Dual-Pump System: Combines a Roots booster pump with a rotary vane vacuum pump for faster evacuation and lower ultimate pressure.

- Precision Control & Automation: Integrated vacuum gauge for accurate monitoring and an automatic vacuum relay for hands-free operation.

- Quiet & Reliable Operation: Built for continuous use with minimal noise and vibration.

- User-Friendly Interface: Equipped with a centralized control panel featuring function buttons and a main breaker for easy and safe operation.

- Portable & Versatile Design: The compact and lightweight frame allows for easy transport, with optional trailer mounting for field use.

- Weatherproof Option: A fully enclosed version is available for outdoor operation in demanding environments.

Advantages of Zanyo Vacuum Pumps and Systems

- Long-lasting Durability:

Built with high-quality materials and precise engineering, our vacuum pumping system is designed for long-term operation, reducing downtime and maintenance costs. - Energy Efficiency:

The system is optimized to consume less energy while maintaining peak performance, helping you reduce operating costs. Its advanced design minimizes power consumption, making it a cost-effective solution. - Low Noise Operation:

Designed for quieter operation compared to traditional vacuum systems, the low-noise technology of our vacuum pump system makes it suitable for sensitive environments and enhances overall user comfort. - Versatility:

Our vacuum pumping system is highly adaptable and can be used in a wide range of applications, from vacuum drying to vacuum distillation and vacuum coating. Its modular design allows it to be tailored to specific requirements. - Easy Maintenance:

The system is designed for easy servicing, with accessible components and low-maintenance requirements. The pumps are built for simplicity and reliability, making routine maintenance fast and straightforward.

How Does a Vacuum Pump System Work

Applications of Vacuum Pumps and Systems

A vacuum pump system is used in various industries and applications where a controlled low-pressure environment is required. These systems remove air and gases from sealed spaces to create a vacuum, which is essential for numerous processes. Here are some of the main areas where vacuum pump systems are used:

A vacuum pump system is used in various industries and applications where a controlled low-pressure environment is required. These systems remove air and gases from sealed spaces to create a vacuum, which is essential for numerous processes. Here are some of the main areas where vacuum pump systems are used:

Partner with ZANYO for Vacuum Pumps and OEM Custom Solutions

ZANYO provides stable vacuum pumps and tailored OEM services for oil purification systems. Every unit goes through strict ISO and CE-certified testing. Our team helps you choose the right model based on your market and technical needs. Production updates, photos, and videos keep your order transparent from start to finish.

Our global after-sales support includes technical guidance, replacement parts, and training to ensure smooth operation. Contact us today to discuss your project or request a quote.

Guide to Zanyo Vacuum Pumps For Oil Purification Systems

Vacuum pumps play a central role in industrial oil purification. They create the low-pressure environment needed for efficient moisture and gas removal, which keeps oil stable and suitable for long-term equipment use. This page introduces how vacuum pumps work in purification systems and what buyers should consider when selecting a unit.

How Vacuum Pumps Support the Purification Process

A vacuum pump lowers the system pressure so moisture can evaporate at a much lower temperature. The reduced pressure helps the oil release dissolved gases and trapped air. The vapor then moves toward the vacuum section and gets removed from the system. This process improves oil dryness and helps maintain performance in demanding applications.

High-Performance Vacuum Pumps Dual-Pump System

Zanyo’s vacuum pump systems feature a dual-pump configuration, combining a Roots pump with a rotary vane vacuum pump. This design is the key to achieving both rapid evacuation and deep vacuum levels in industrial applications.

Fast Vacuum Generation

- The Roots pump delivers high pumping speed, quickly reducing chamber pressure.

- Ideal for processes requiring rapid evacuation or continuous operation, such as oil purification, vacuum drying, and distillation.

Deep Vacuum Capability

- The rotary vane pump ensures lower ultimate pressure, maintaining stable deep vacuum conditions.

- Deep vacuum environments are critical for transformer oil purification, vacuum coating, and precision laboratory experiments.

Stable and Energy-Efficient Operation

- Dual pumps work collaboratively to prevent overloading a single pump, extending equipment life.

- Smooth operation reduces energy consumption and minimizes maintenance frequency and costs.

Automated Control

- Equipped with vacuum relays and gauges, the system can automatically adjust pump operation.

- Simplifies operation while ensuring precise and reliable vacuum levels.

The dual-pump system not only speeds up vacuum generation but also achieves deeper vacuum levels, making it the preferred solution for industrial and laboratory applications that demand high efficiency and precision.

Why Vacuum Pumps Matter in Oil Purification

Industrial oil often carries water and air. These contaminants weaken insulation strength, speed up oxidation, and cause sludge. Heating alone cannot remove deep moisture. Vacuum technology speeds up dehydration and supports stable operation in transformer oil units, turbine systems, and industrial filtration equipment.

Common Vacuum Pump Types Used in Purification

- Rotary Vane Vacuum Pump

This pump provides the main vacuum level. It is steady during long duty cycles and handles high vapor loads well. - Roots Vacuum Pump

This pump increases pumping speed and improves overall efficiency. It works with a rotary vane pump when fast dehydration is required.

Key Features Buyers Look For

Reliable vacuum stability.

Smooth performance under constant vapor load.

Simple maintenance.

Good moisture removal results during continuous operation.

Where Vacuum Pumps and Systems Are Used

Transformer oil purification.

Turbine and lubrication oil dehydration.

Industrial oil recycling.

Power station and substation maintenance.