Zanyo Oil Purifier:

Improving Oil Life, Efficiency, and Sustainability

ZANYO is a leading manufacturer and supplier of high-performance oil purifiers designed to remove moisture, gases, and particles from oils, improving oil performance and efficiency. Our machines efficiently handle hydraulic oil, lubricating oil, transformer oil, and waste or used oil, using advanced filtration, dehydration, and degassing technologies to ensure cleaner, longer-lasting oil for industrial applications.

Why Choose Zanyo For Oil Purification Systems

We guarantee safety, reliability, and top performance. From pre-sale guidance to on-time delivery and professional after-sales support, we make every step clear and dependable. Our global support ensures easy access to products anywhere. We listen to customers, improve continuously, and deliver real value. Partner with ZANYO to increase efficiency, reduce risks, and keep your operations running smoothly.

What Is an Oil Purifier?

An oil purifier is a vital industrial machine designed to remove contaminants—such as water, particulates, and gases—from various oils, including hydraulic, lubricating, transformer, and cooking oils. By ensuring the oil remains clean and free from impurities, oil purifiers play a crucial role in extending the lifespan of machinery, reducing maintenance costs, and promoting environmental sustainability.

Importance of Oil Purification

Extended Oil Life: An oil purifier removes contaminants like water, gas, and particles, helping to prolong the life of your oil. This reduces the need for frequent oil changes and keeping your machinery running longer.

Improved Equipment Performance: Clean oil keeps your equipment running smoothly by preventing clogging, wear, and tear. This boosts the efficiency of your machinery, reduces downtime, and lowers the risk of unexpected breakdowns.

Cost Savings: By reducing the need for frequent oil replacements and minimizing maintenance costs, using an oil purifier machine can lead to significant long-term savings for your business.

Environmentally Friendly: Reusing purified oil reduces the amount of waste oil, minimizing disposal needs and environmental impact. This contributes to more sustainable practices, helping your business operate in an eco-friendly manner.

Types of Oil Purifiers

We offer two types of oil purifier machines: Vacuum Oil Purifier and Centrifugal Oil Purifier, each based on different oil purification technologies with distinct principles and objectives.

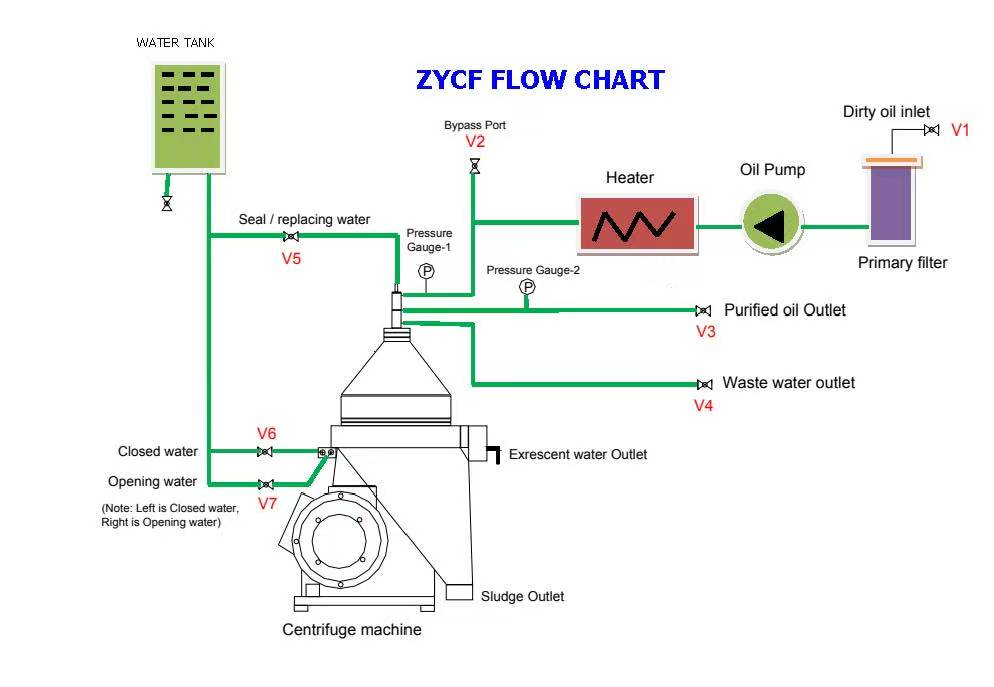

Centrifugal Oil Purifier uses centrifugal filtration technology to clean oil. The oil spins at high speed inside the machine, which pushes heavier particles, sludge, and emulsified water outward while leaving clean oil in the center. This method efficiently removes solid impurities and moisture without chemicals.

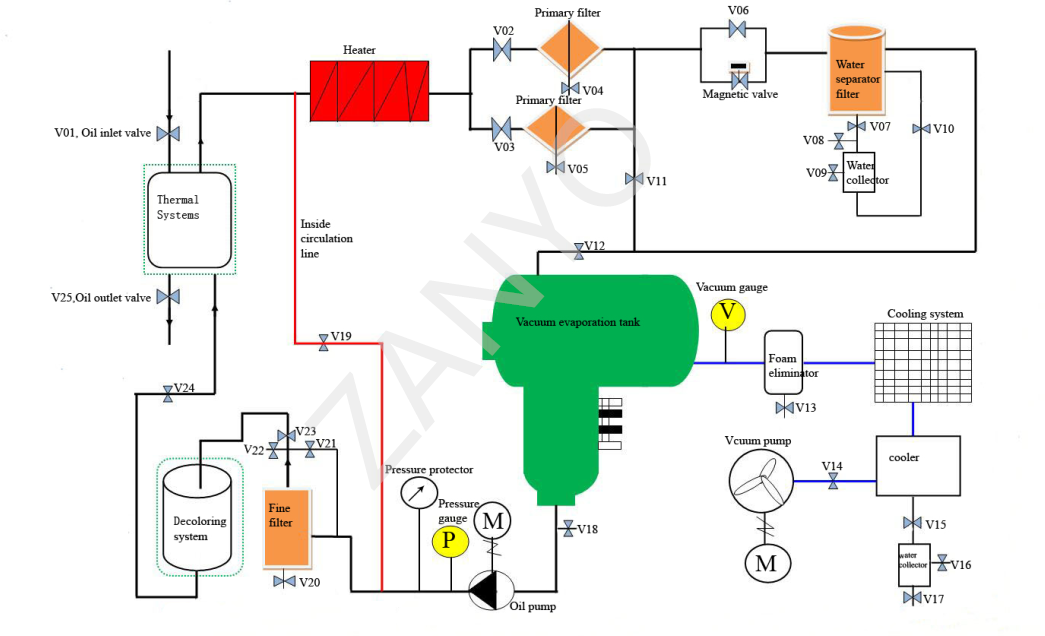

Vacuum Oil Purifier uses vacuum filtration technology to purify oil. By lowering the pressure, water and dissolved gases evaporate more quickly, while small particles are filtered out. This results in dry, clean oil that is protected from corrosion and degradation.

Vacuum Oil Purification System

Centrifugal Oil Purification System

When to Use an Oil Purifier

An oil purifier should be used whenever oil becomes contaminated with dirt, water, sludge, or gases.

Hydraulic machinery, engines, turbines, and transformers can introduce particles, metal wear, or moisture into the oil during operation. Over time, these contaminants can cause corrosion, sludge buildup, reduced lubrication, and machine wear. Using an oil purifier restores oil quality, and extends its service life, helping equipment run smoothly and reducing maintenance costs.

In other industries, such as food processing, manufacturing, or waste oil collection, oil purification supports recycling used oil. After purification, the oil can be processed into biodiesel, industrial lubricants, or raw materials for chemical production, turning waste into valuable resources and reducing environmental impact.

Maintenance and Care

- Routine Cleaning: Remove accumulated sludge, dirt, and debris from filters and components to maintain optimal filtration efficiency.

- Filter Replacement: Replace filter elements according to the manufacturer’s schedule to prevent clogging and maintain high-efficiency oil filtration.

- System Inspection: Regularly inspect pumps, seals, and other components for wear and tear. Early detection prevents costly breakdowns.

- Oil Quality Monitoring: Use oil testing equipment to monitor moisture content, particle levels, and overall oil condition. Maintaining clean oil ensures machinery operates smoothly.

FAQ

1. What does an oil purifier do?

An oil purifier is a machine that cleans oil by removing dirt, water, and other impurities. It improves the quality of oil and extends its life. Industrial oils, like hydraulic oil, transformer oil, and lubricating oil, can get dirty during use.

Using an oil purifier keeps the oil clean, reduces machine wear, and helps equipment run smoothly. It also prevents damage caused by corrosion or sludge. In short, an oil purifier makes old or dirty oil usable again and protects machinery.

2. How to use an oil purifier?

Using an oil purifier is easy. After connecting to the oil system, the pump moves the oil through the purifier automatically. The system runs on its own, removing dirt, water, and particles without manual operation.

The process is fully automatic, but it is still important to check oil levels and clean filters regularly according to the manufacturer’s instructions.

3. What is the principle of an oil purifier?

An oil purifier works by cleaning oil using vacuum or centrifugal force.

In a vacuum purifier, water, air, and dissolved gases are removed from the oil, which prevents corrosion and improves its quality. In a centrifugal purifier, the oil spins at high speed, and heavier particles, sludge, and water are pushed outward while clean oil stays in the center.

Both methods efficiently remove impurities, extend oil life, and protect machinery from wear and damage.

4. What is the process of oil purification?

First, used oil passes through an initial filter to remove large particles, debris, and impurities that could harm equipment. Next, the oil is heated to reduce viscosity, making it thinner and easier to separate moisture and gases.

The oil is then transferred into a tank for centrifugal or vacuum treatment, which removes smaller particles and water. Finally, the oil goes through a fine filter to remove any remaining impurities, ensuring it is clean and ready for reuse.