Regenerated transformer oil undergoes a systematic process to restore its quality. This process removes impurities, moisture, and dissolved gases, making the oil almost as good as new. You benefit from oil that meets safety and performance standards. It offers a cost-effective and eco-friendly solution for maintaining electrical equipment.

Key Takeaways

- Regenerated transformer oil becomes clean by removing dirt and water. It works almost like new oil.

- Picking regeneration instead of buying new oil can cut costs by half. It also reduces waste and helps the environment.

- Checking and caring for regenerated oil keeps it working well. This helps electrical equipment last longer.

Importance of transformer oil regeneration

Role of transformer oil in electrical equipment

Transformer oil plays a vital role in ensuring the safety and performance of electrical equipment. It provides insulation and cooling, which are essential for managing high voltages and temperature rises.

The oil also helps extinguish arcs, preventing damage during electrical faults. Additionally, it dissolves gases generated from oil degradation and insulation deterioration. This allows you to monitor transformer health through dissolved gas analysis (DGA).

Testing the oil’s dielectric strength, such as through breakdown voltage assessments, ensures it can withstand electrical stresses. These properties make transformer oil indispensable for reliable equipment operation.

Challenges with used transformer oil

Over time, transformer oil degrades due to exposure to heat, oxygen, and moisture. This leads to the accumulation of impurities, sludge, and dissolved gases, which reduce its insulating and cooling capabilities.

Aged oil also exhibits lower breakdown voltage, increasing the risk of equipment failure. If left untreated, these issues can compromise the efficiency and safety of your electrical systems. Regular maintenance becomes crucial to address these challenges and prevent costly repairs or replacements.

Advantages of regeneration over replacement

Regenerating transformer oil offers several benefits compared to complete oil replacement. It is significantly more cost-effective, often reducing expenses by up to 50%. Regeneration also minimizes waste, aligning with environmental sustainability goals.

Unlike replacement, it cleans solid insulation, restoring the oil’s properties and extending the lifespan of your equipment. Furthermore, the process requires minimal downtime, ensuring uninterrupted operations.

By choosing regeneration, you achieve a balance between performance, cost savings, and environmental responsibility.

Step-by-step process of producing regenerated transformer oil

Heating and filtration

The first step in producing regenerated transformer oil involves heating and filtering the used oil. Heating raises the oil’s temperature, reducing its viscosity and making it easier to remove impurities.

Filtration eliminates solid contaminants like sludge and metallic particles, which can degrade the oil’s performance. Studies show that this process also helps remove hazardous substances, such as PCBs, by using advanced filtration techniques.

Vacuum dehydration

Vacuum dehydration removes moisture and dissolved gases from the oil. Moisture can significantly reduce the dielectric strength of transformer oil, increasing the risk of equipment failure.

By applying a high vacuum, this process extracts water and gases efficiently. This step is crucial for ensuring the reliability of your electrical equipment.

Adsorption using silica gel or other media

In this stage, adsorbents like silica gel or activated clay remove acids, sludge, and oxidation by-products. Silica gel, in particular, has proven to be highly effective due to its superior capacity for removing impurities.

Research shows that silica gel can significantly lower residual soap content and trace metals, making it an ideal choice for oil regeneration.

Recirculation and quality testing

The final step involves recirculating the regenerated transformer oil back into the system and conducting quality tests. Recirculation ensures the oil integrates seamlessly with the transformer, maintaining its functionality.

Quality tests, such as dielectric strength and moisture content analysis, confirm that the oil meets industry standards. This step guarantees that the regenerated oil performs as effectively as new oil, offering a cost-effective and sustainable solution for your equipment.

Benefits of regenerated transformer oil

Cost-effectiveness for industries

Regenerating transformer oil offers a practical way to save money. Instead of replacing used oil, you can restore its properties at a fraction of the cost. This process reduces expenses by up to 50%, making it an economical choice for industries managing large-scale electrical equipment.

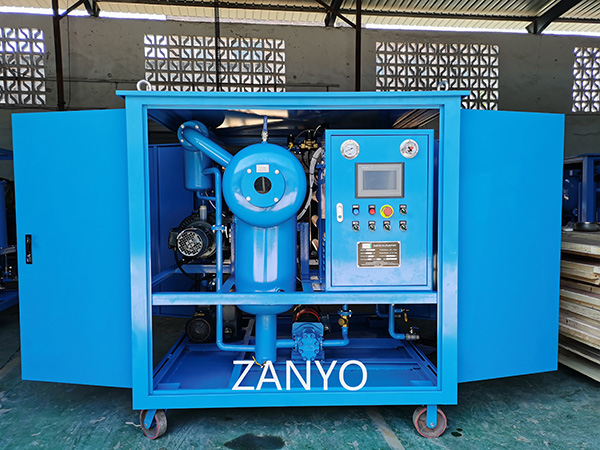

The ZANYO Oil Purifier plays a key role in this cost-saving approach by efficiently removing impurities and revitalizing the oil. Additionally, regeneration minimizes downtime, allowing your operations to continue without significant interruptions.

By choosing this method, you achieve long-term savings while maintaining the performance of your equipment.

Environmental sustainability

Regenerated transformer oil supports your sustainability goals by reducing waste and conserving resources. When you regenerate oil, you prevent the disposal of used oil, which can harm the environment. This process also reduces the demand for new oil production, lowering the carbon footprint associated with manufacturing. By opting for regeneration, you contribute to a cleaner and greener future.

Enhanced performance and reliability

Regenerated transformer oil restores the chemical and physical properties of used oil, ensuring your equipment operates safely and efficiently. The process enhances the oil’s dielectric strength and thermal conductivity, which are critical for reliable transformer performance.

Unlike new oil, regenerated oil undergoes a revitalization process that extends its useful life and reduces operational costs. Tests like oxidation stability and oil sample evaluations confirm its ability to resist degradation and maintain reliability.

With ZANYO’s Oil Purifier, you can trust that your regenerated oil meets high-quality standards, ensuring the longevity of your electrical systems.

| Benefit Type | Description | Cost Impact |

| Process Efficiency | Enhances transformer reliability through advanced purification technologies. | Long-term operational savings |

| Cost Reduction | Cost is 90% lower than traditional oil change methods. | Significant cost savings |

| Environmental Benefits | Improves insulation and safety performance without damaging oil properties. | Positive environmental impact |

By choosing regeneration, you maintain the oil’s antioxidant properties, reduce wear on components, and meet new oil standards. This sustainable solution ensures your equipment operates efficiently while minimizing environmental impact.

Ready to maximize the life of your transformer oil?

ZANYO specializes in high-quality oil purification machines designed to enhance the longevity and performance of transformer oil. Our advanced system is specifically engineered to maintain transformer oil, ensuring optimal efficiency and reliability. With a focus on durability and cost-effectiveness, we help businesses extend equipment life and reduce maintenance costs.

Reach out to us today to find out more about our transformer oil purification system.

Transformer Oil Filtration Device

FAQ

What is the lifespan of regenerated transformer oil?

Regenerated transformer oil can last as long as new oil. Its lifespan depends on proper maintenance and regular testing to ensure optimal performance.

Can you regenerate transformer oil multiple times?

Yes, you can regenerate transformer oil multiple times. The process restores its properties, making it reusable while maintaining safety and performance standards.

Is regenerated transformer oil safe for all transformers?

Yes, regenerated transformer oil is safe for most transformers. It meets industry standards and undergoes rigorous testing to ensure compatibility and reliability.