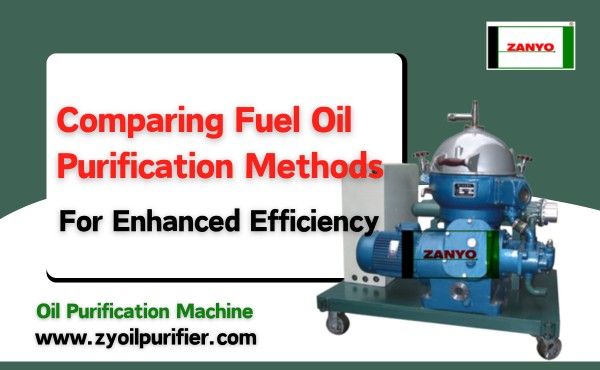

Centrifugal oil purifiers use centrifugal force to separate impurities from oil. This process relies on density differences between contaminants and the oil itself. By removing unwanted particles, oil purification ensures better performance and longer life for machinery. This method plays a vital role in maintaining clean, efficient lubrication systems.

Key Takeaways

- Centrifugal purifiers spin oil fast to remove dirt and impurities.

- Keeping purifiers clean is important to work well and avoid problems.

- Ships and power plants use purifiers to help machines last longer.

The Basics of Centrifugal Oil Purification

What is a centrifugal oil purifier?

A centrifugal purifier is a device designed to clean oil by removing impurities such as water, sludge, and solid particles. It operates using centrifugal force, which separates contaminants based on their density. This method ensures that the oil remains clean and effective for use in machinery.

Centrifugal oil purifiers are widely used in industries where maintaining oil quality is critical. They are especially effective in applications requiring continuous purification, such as marine engines and power plants. A high-speed centrifugal purifier can process large volumes of oil efficiently, making it an essential tool for industrial operations.

Key components of a centrifugal purifier

A centrifugal purifier consists of several key components that work together to achieve effective oil purification:

- Bowl Assembly: The core part of the purifier where separation occurs. It rotates at high speeds to generate centrifugal force.

- Disc Stack: A series of conical discs inside the bowl that increases the surface area for separation.

- Inlet and Outlet Ports: Channels for oil to enter and exit the purifier during operation.

- Drive Mechanism: A motor or other system that powers the rotation of the bowl.

- Sludge Discharge System: A mechanism to remove separated impurities from the purifier.

Each component plays a vital role in ensuring the centrifugal oil purifier operates efficiently. Together, they enable the device to maintain oil quality and extend the lifespan of machinery.

How Oil Purification Works in a Centrifugal Purifier

Step-by-step explanation of the purification process

The purification process in a centrifugal purifier begins with the contaminated oil entering the device through the inlet port. The oil flows into the bowl assembly, which rotates at high speed. This rotation generates centrifugal force, pushing heavier contaminants outward toward the bowl’s walls.

Inside the bowl, the disc stack plays a critical role. The conical discs create narrow channels that guide the oil and contaminants. As the oil moves through these channels, lighter particles and water separate from the heavier impurities. Clean oil collects in the center of the bowl and exits through the outlet port.

The separated contaminants, including sludge and water, accumulate near the bowl’s outer edge. The sludge discharge system periodically removes these impurities, ensuring uninterrupted operation. This step-by-step process ensures effective oil purification and maintains the oil’s quality for extended use.

The role of centrifugal force in separating impurities

Centrifugal force is the core working principle of a centrifugal purifier. When the bowl rotates at high speed, it creates a powerful outward force. This force acts on the oil and contaminants, separating them based on their density.

Heavier contaminants, such as sludge and solid particles, move outward due to their higher density. Lighter substances, including water and oil, remain closer to the center. The centrifuge’s design ensures precise separation, allowing clean oil to flow out while impurities are collected for removal.

By leveraging centrifugal force, the purifier achieves efficient oil purification. This mechanism minimizes contamination and extends the oil’s usability, making it essential for industries that rely on clean lubrication systems.

Benefits and Applications of Centrifugal Purifiers

Efficiency in removing contaminants

Centrifugal purifiers excel at removing contamination from oil. Their high-speed rotation generates centrifugal force, which separates impurities based on density. Heavier particles, such as sludge and solid debris, move outward, while lighter substances like water and oil remain closer to the center. This precise separation ensures clean oil for machinery.

The purification of lube oil becomes more effective with the use of centrifugal purifiers. These devices handle large volumes of oil without compromising efficiency. By reducing contamination, they enhance the performance of lubrication systems and extend the lifespan of equipment. Industries rely on this technology to maintain operational reliability.

Industrial applications (e.g., marine, power plants)

Centrifugal purifiers play a vital role in industrial settings. In marine applications, they ensure the continuous purification of lube oil for ship engines. Clean oil reduces wear and tear, improving engine efficiency and reliability during long voyages.

Power plants also benefit from oil purification systems. Turbines and generators require clean lubrication to operate smoothly. Centrifugal purifiers remove contaminants that could damage critical components. Their ability to handle high volumes of oil makes them indispensable in these environments.

Other industries, such as manufacturing and automotive, use centrifugal purifiers to maintain machinery. By preventing contamination, these devices reduce maintenance costs and downtime. Their versatility and efficiency make them a preferred choice across various sectors.

Conclusion

Centrifugal purifiers play a crucial role in maintaining oil quality. They effectively remove impurities, ensuring clean lubrication for machinery.

Key Benefits:

- Enhanced equipment performance

- Reduced wear and tear

- Extended operational life

Industries such as marine and power generation depend on these purifiers. Their ability to handle large volumes of oil makes them indispensable for reliable operations.

Maximize the life of your industrial oil with ZANYO‘s centrifugal oil purification machine. Our system delivers reliable filtration to improve oil performance and reduce maintenance costs. Get in touch with us today to discover how ZANYO’s solutions can help optimize your equipment and keep operations running smoothly.

FAQ

What types of impurities can centrifugal purifiers remove?

Centrifugal purifiers remove water, sludge, and solid particles. These impurities are separated based on their density differences during the purification process.

How often should a centrifugal purifier be cleaned?

Cleaning frequency depends on oil contamination levels. Regular maintenance ensures optimal performance and prevents the buildup of impurities in the purifier.

Can centrifugal purifiers handle different types of oil?

Yes, centrifugal purifiers work with various oils, including lubricating and fuel oils. Their design accommodates diverse industrial applications.