What Is Lube Oil Purifier System ?

Many industries are abreast with machinery and these systems help to function properly on a day-to-day basis. Lubricating oil is one crucial thing when it comes to the smooth running of machines. They help in reducing and overcoming the heat, and also reduce the wear and tear between the surfaces. But lubricating oil is easy to be polluted by water and emulsified, thereby negatively affecting the lubrication property. The wasted lubricating oil composition is complex , with high water content and exists with emulsion.

There need a machinery which can be satisfied for efficiently demulsification and dehydration of the emulsified lubricating oil-Lubricating Oil Purifier.

ZANYO Lube & Hydraulic Oil Filtration Systems

What is a lube oil purifier systems?

The Oil Purifier is suitable for treating turbine oil, hydraulic oil, anti-wear oil, bearing oil or high-viscosity lubricating oil, and also for purifying the oil with high water content or turbid emulsification. It can effectively dehydrating and removing impurities from old oil, final oil becomes limpid. Generally used for the purification of hydraulic oil and lubricating oil etc. When the oil contains too much water and impurities, it must be treated again.

A lube oil purifier basically purifies every type of lube oil. This can remove impurities, gas, moisture, acid, hydrocarbons etc., the filtration treatment makes it clean and good for use again. A good lube oil purifier extends the lifetime of the machinery.

It is generally applied in power plants, power stations, all industrial and mining enterprises, etc.

How is a lube oil filtration system working?

An adequate filtration system is required to keep the lube oil at an optimum level. A lube oil filtration system ensures that the oil stays out of any impurity. A lube  oil purifier also ensures that the oil performs its tasks efficiently.

oil purifier also ensures that the oil performs its tasks efficiently.

Lube oil is not something that will wear out! However, the quality of the lube oil may decrease with time. This happens due to the contamination that may take place. Dirt, water, sludge, metals are some of the contaminants in lube oil.

A centrifugal purification process is most commonly used. The first method of batch purification process involves removing the contaminated oil completely and transferring it to a reservoir. The oil that reaches the reservoir is cleaned and purified. This is a method that is followed in a piece of non-operational machinery.

The second one is a continuous process. This process is done wherein the centrifuge removes a portion of the oil from the storage tank. The cleaning, recycling, and restoring process is done in the tank itself. Although this process can be tried on an operating machine, it is not so swift and adept as the batch process.

Lubricating Oil Purifier Function

Particle filtration is the basic process that is required to keep the contaminants off the hydraulic oil. However, sometimes there are loopholes during the engineering process of the machinery and this leads to inefficient filtration. The primary functions of the hydraulic system outweigh the efforts of bringing in a mechanism to filter the oil. Thus, the filtration process is often neglected. This can result in the purifiers often malfunctioning. The purifier is often the underestimated part of the design.

Controlling the contamination also means not allowing the contaminants to enter the system. The centrifugation system, periodic purification systems, magnetic filtration are various types of systems.

Particle contamination, water separation, gas and entrained air removal, acid removal, varnish removal are some of the processes that the oil purifier performs. The hydraulic oil purifier machine works at its best when overhauled. It is also effective against any contaminants.

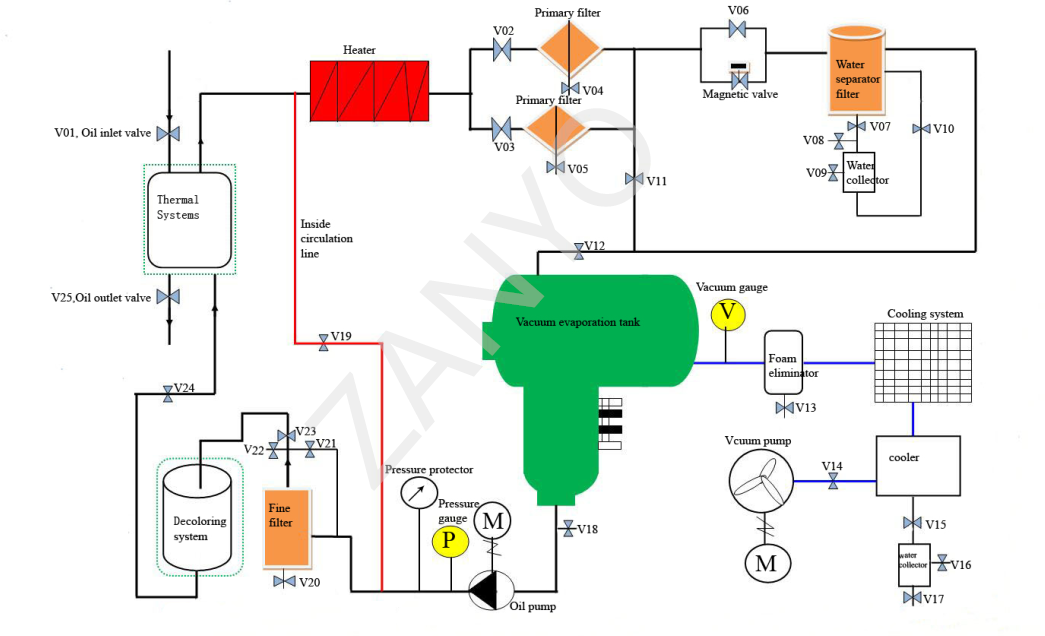

This Lube hydraulic oil purification system typically aims at purifying the hydraulic oil. This hydraulic oil purifier machine is widely used in transportation, metallurgy, manufacturing, food, chemical, and other industries. Capillary condensation is undergone by the oil post the primary filtration process. This process also ensures that the small droplets turn out as bigger droplets and ultimately get separated from the oil. A Vacuum system is used to remove the dissolved water and this is done through a heating process and evaporation. A vacuum pump-out is also employed for the same.The Lube oil passes through a coarse oil filter system as the first process. It also gets absorbed by the heating system through a negative vacuum pressure. A degassing tank that is present in the system heats the oil and separates the water from the system.

Fully kinds of Lube Oil Purifier Machine Supply

This machine has an advanced system. This machine when connected to an oil station or hydraulic oil tank is capable of performing the oil filtration online or offline. An oil-water separation system is the highlight of the machine. Advanced vacuum technology is employed to carry out the water-oil separation process. A full fledged filtration system is in-built to ensure that the lube oil stays away from contamination. This is ensured through a continuous filtering process. A heating system and a defoaming system are also employed in the machine supply.

The heating system ensures uniform heating of the oil in the machine. A reliable heating system is to be employed to achieve this. The defoaming system ensures safety and stability to the machinery. An oil filter element introduced in the machine supply ensures that any minute impurity is filtered and kept away. This ensures that the oil is typically pure and the machines function efficiently. A condensing system is also a part of the machine supply. The condensing system makes sure that the cooling of air takes place when it comes to moist air or gas. This is responsible to extend the lifetime of the machine.

Conclusion

If there’s a lifesaver for any oil-wetted machinery, then call it the lube oils. The importance of lube oils is paramount in pieces of machinery. These lube oils practically ensure that the machine works perfectly. Not only does it offer a smooth movement of all internal components, but it also carries out some vital operations like cooling, lubrication, cleaning, and sealing.

The development of higher standard devices and better emission standards has inspired manufacturers to build the best filters. The lube oil purifier machines are very effective. A fuel oil purifier systemremoves the contaminants in it and makes it efficient and generates better revenues through lesser oil changes.

The transformer oil in machinery can also get contaminated and a transformer oil purifier system is used to remove the moisture in the gas.Water and solids are both removed in a single purification process. The effective cleaning mechanisms and the filtration of smaller-sized particles make the lube oil proficient. This also enhances or increases the lifetime of the machinery. This certainly means better productivity and greater revenue. The cost of ownership of this machinery is ultimately low.

A lube oil filtration process is hence of greater importance in any machinery. If you are interest ZANYO lube / hydraulic oil purification systems , welcome to get in touch with us. We are ready to serve you!